Qualification at the open and modular training system for new and modernized job profiles on the subject of digital transformation

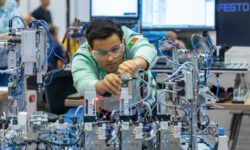

The ability of manufacturing companies to compete in today’s market is dictated by the speed at which they can successfully complete the digital transformation. In many cases, however, there is a distinct lack of skilled workers for this very job. That is why we are currently witnessing the appearance of new career profiles such as management assistants for digitalization management, accompanied by the modernization of established profiles such as mechatronics engineers or IT specialists. With the XITE Automax 600, Bosch Rexroth has developed a training system for initial and further education in these disciplines. It brings abstract digitalization content to life and shows the direct results of the students’ work in a practical manufacturing context.

In developing its new training system for initial and further education, Bosch Rexroth harnessed the practical experience gathered in Bosch plants all across the globe. Entire processes have been successfully digitalized in these plants for many years now. The training system provides open interfaces and programming environments, ranging from the field level to IT systems, and promotes interdisciplinary work encompassing computer science, automation and intralogistics. A wide range of exercises allows students to gain first-hand experience in the practical relationships between productivity, quality and flexibility in production.

Modular and expandable

The XITE Automax 600 training system consists of individual modular stations, which thematize a digitalized manufacturing process encompassing everything from initial removal from a magazine to processing with a press and storage in a high-bay warehouse. The system can also be supplemented with optional extras, such as a manual workstation, a 7-axis cobot and an autonomous transport system for loading and unloading the line.

The exercises cover the entire value stream. The coordinated movements of the modules and the visualization of data and user interfaces are programmed by the students using different controls.

From the field level to the cloud

The training system is based on an open platform and simplifies the connection to various higher-level IT systems, ranging from production planning and control to cloud applications such as data analysis and AI-based machine learning. The open nature of the system makes it compatible with software expansions such as ERP and MES, thus allowing learning content from commercial IT or production management to be integrated.

In the practical exercises, which are based on the German core curriculums for new and modernized professions, the training system covers important topics of the future, including IT competence, data management, digitalization and connectivity.

About Bosch Rexroth Academy

Always a step ahead with Bosch Rexroth Academy

Expert knowledge and qualification create a decisive advantage in global competitiveness. Over 225 years of experience as a global industrial company and leading specialist in Drive and Control Technology has made us unique experts in developing innovative products and technologies while maximizing process efficiency. Bosch Rexroth Academy Rexroth offers a practice-oriented portfolio of didactic solutions in the fields of Hydraulics, Automation and Pneumatics, setting benchmarks in the preparation of specialized and integrated know-how. Training and training systems from Bosch Rexroth are precisely tailored to the qualification levels required by the industry as well as educational institutions.

We are the education partner for high-end technical education on the exciting path of digital transformation.

Article Submitted by

Nicola Schmitt

Bosch Rexroth AG

GERMANY