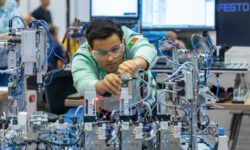

The Sorting System Compact 4.0 is Christiani’s most recent product innovation. In order to offer the best possible training solutions for automation technology, the existing Mechatronic System SSC2P2H has been extended and updated. The Sorting System Compact 4.0 now meets the high standards of smart manufacturing. Key features of the new mechatronic system are the following:

cloud-based control functions — site-independent live monitoring — product tracking via RFID

In a clear design, the compact mechatronic system displays important applications of industry 4.0 within the production process so future professionals have high tech and up-to-date training opportunities. Generally, split into a processing and a sorting unit the system covers a complete production line as both segments are able to communicate with one another. The following sequences of production are illustrated:

• material supply and separation of workpieces via belt conveyor

• workpieces delivery via belt conveyor, handling unit and linear axes

• check-up of material properties and positions with subsequent sorting

• processing in a press

• storage in the ASRS

The Sorting System Compact 4.0 offers you to teach your students and trainees amongst others in the following fields:

• basics in mechatronics and automation

• PLC-programming, web-programming

• optimizing of HMI (Human Machine Interface)

• principles and applications of smart manufacturing

• user management via RFID

• IO-Link technology, field buses

• online control via IoT dashboards and mobile devices

• order management via MES (Manufacturing Execution System)

• cloud-computing

• node-RED programming, MQTT messaging

• information on components via QR-codes

Get more information on the new Sorting System Compact 4.0 by contacting us directly via e-mail: info@christiani-international.com.

Or feel free to check our website: www.christiani-international.com

Article submitted by:

Katharina Schmelzle

Dr.-Ing. Paul Christiani GmbH & Co. KG, Germany