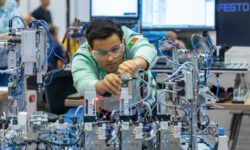

Agile Production Simulation by fischertechnik

Digitalised production processes can be simulated in detail on a small scale with fischertechnik’s revolutionary Agile Production Simulation, for instance with a driverless transport system and quality control using artificial intelligence. The compact simulation model provides a unique opportunity to learn about and simulate future technologies using a hands-on approach.

The factory of the future has been the subject of many research projects in science and the industry. Future-oriented companies are relying on automation, modularity, artificial intelligence and agility to remain competitive. In order to advance these topics in the industry and research, students, apprentices and members of staff require the corresponding skills and awareness to handle complex issues. This is where the Agile Production Simulation learning concept comes in. It simulates processes such as quality control using artificial intelligence or driverless transport systems on a small scale, recreating automated processes from incoming goods to modular production and quality control. The accompanying educational material translates the hands-on simulated processes into future skills for learners. The model’s digital twin significantly enhances the learning experience. Agile Production Simulation is a factory consisting of flexible and combinable modules. Starting at the incoming raw goods, the material flow passes through an automated high-bay warehouse, various production stations such as a milling or drilling station and AI quality control to the outgoing goods. A driverless transport system (DTS) with omniwheels transports workpieces between the individual stations, ensuring an agile production process tailored to customer needs. The DTS can be charged at a charging point without changing batteries, if required. Each workpiece contains an NFC tag where the production data is recorded for digital traceability. The factory produces workpieces in different colours with various processing features. Agile production enables product-specific manufacturing steps within a lean process without the need for set-up time. Agile Production Simulation is controlled by a central control system (Raspberry Pi 4 Model B) connected to the controllers of the individual factory modules, SPS Siemens S7 1200. Various communication protocols, such as the MQTT protocol (Message Queuing Telemetry Transport), allow the modules to connect and work together. Cloud-based real-time monitoring provides dashboards to control processes and visualise the factory status. It can also determine KPIs such as cycle times and overall equipment effectiveness (OEE). An online store simulates the customer’s workpiece order process. A moveable camera can be controlled via the dashboard to simulate the principle of remote maintenance. The Quality Control with AI module makes the complex topic of machine learning tangible while demonstrating its uses in a production environment. Based on the concept of supervised learning, the machine learning modules are implemented with the AI tool Tensorflow. Agile Production Simulation was developed in cooperation with experts from the Karlsruhe Institute of Technology (KIT), the software company OMM Solutions GmbH and the University of Stuttgart. The model will soon be available for anyone who wants to get to grips with the factory of the future.

www.fischer.group/de-de/newsroom/presseinformationen

www.fischertechnik.de

The Quality Control with AI module from fischertechnik’s Agile Production Simulation facility makes the complex topic of machine learning tangible while demonstrating its uses in a production environment. The model will soon be available for anyone who wants to get to grips with the factory of the future.(image: fischertechnik)

About

The fischer Group of Companies The fischer Group of Companies, headquartered in Waldachtal in Germany’s northern Black Forest, generated sales of 1.16 billion euro in 2023 with a global workforce of around 5,900 employees. The family-owned company operates 52 subsidiaries around the world and exports to around 120 countries. It includes the five divisions: fischer fixing systems, fischer Automotive, fischertechnik, fischer Consulting and fischer Electronic Solutions. fischer fixing systems is the technological market leader in key areas of fixing technology. fischer offers products that deliver technical perfection to a wide range of customers, from do-it-yourselfers to tradespeople to key account partners. fischer Automotive manufactures high-quality parts for vehicle interiors. The company is highly competent in the plastics processing segment and is an important partner for the automotive industry. Its range of products includes air vents, cup holders, trays and multi-function components. With its construction kits, fischertechnik is active in both the toymaking and the educational sector. fischertechnik is one of the last remaining toy makers to exclusively develop and produce in Germany. fischer Consulting evolved from the competence developed in the company itself, which includes the fischer ProcessSystem with its central aim of permanent improvement for the ultimate benefit of the customer. fischer Consulting advises small and medium-sized businesses, government agencies and major companies on their path towards lean and efficient processes. fischer Electronic Solutions develops and manufactures electronic solutions including product and system developments based on the latest technology as well as custom production orders processed in the company’s own production facilities. As an experienced provider of development and production services for custom systems such as multi-touch solutions made of glass and the corresponding controller units, fischer Electronic Solutions forms the perfect link between the customer and the final product. www.fischer.group

Article Sumbitted by

Sandra Roth

fischertechnik GmbH

Germany