New tools to build essential dimensional metrology skills.

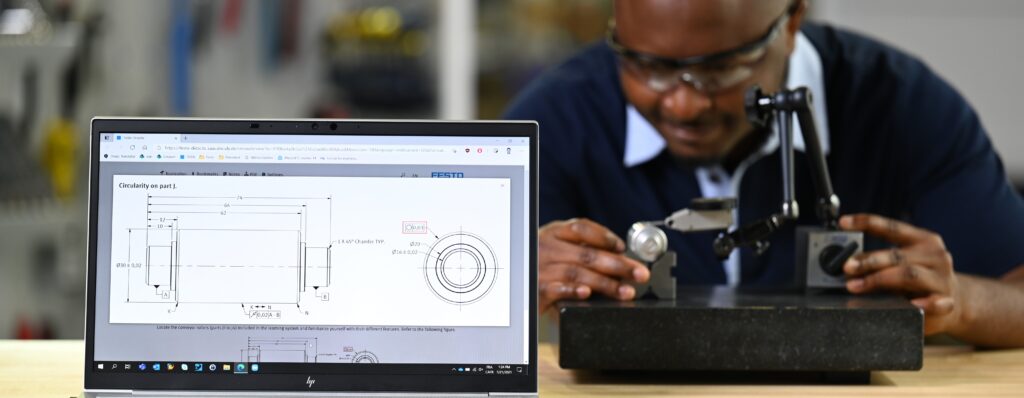

Product dimensional inspection skills are key for manufacturing excellence and quality control in a globalized, competitive world. Expertise in basic dimensional metrology, geometric dimensioning and tolerancing (GD&T) or geometrical product specifications (GPS), and statistical process control (SPC) should become second nature so that workers can correctly apply these skills as soon as they hit the shop floor.

“This fundamental skills area is essential for a wide range of workers. Therefore, we developed new pragmatic learning solutions that meet training needs in school and in the industry”, says Dr Hans Jörg Stotz, Member of the Management Board, Festo Didactic.

Multimedia course material guides learners – students, trainees, or workers – through a large range of learning activities and projects arranged in a sequence of increasing complexity. Hands-on experimentation is carried out using turnkey equipment sets that combine necessary instruments, accessories, and industrial-grade test parts specially designed to maximize the pedagogical value. Modularity of the training packages entails flexibility: training can be adapted to individual needs, whether in the framework of a formal course or as self-guided learning.

“We go beyond measuring tasks and strictly technical knowledge. We give the opportunity to develop transversal competencies, such as decision-making problem-solving skills, required for today’s workplace”, says François-Philippe Paradis, Product Manager of Industrial Trades learning solutions, Festo Didactic.

For more information:

Interested? Here you can watch our short video presentation: https://bit.ly/Dimensional-Metrology-TPs

Visit our website:https://bit.ly/Dimensional-Metrology-Solutions

Article Submitted by

Franziska Hentschel

Festo Didactic SE

Germany